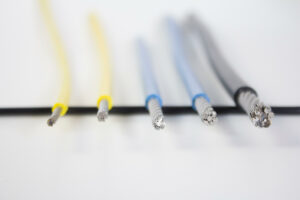

Performance Wire and Cable supplies top-of-the-line tracer and stainless steel HDD wire to be used in direction drilling work. There are a variety of tracer wire types and sizes available to help meet your specific criteria in your next HDD project.

The technique of horizontal directional drilling was made popular in the 1970s. During that time, it was used to install petroleum and natural gas pipes. Starting in the 1990s, water pipes, cables, and other pipes began to be laid using the same process.

Process of Horizontal Directional Drilling

Horizontal directional drilling occurs in a few stages. First is the pilot drill where a rig (i.e. the drilling machine) pushes a drilling head, followed by a hollow pipe, through the ground. Drilling fluid is then applied through the hollow pipe to prevent the drill hole from collapsing. Second, the rig pulls a clearing device through the drill hole. Behind the clearing, the device is a pipe with which drilling fluid can be applied to the drill hole directly. Depending on the desired diameter of the production pipe, this process is repeated several times. The final stage is drawing in the production pipe. The clearing device is disconnected from the rig and the production pipe is attached. The rig slowly pulls the pipe through the drilling hole.

Tracer wire systems are important for horizontal directional drilling processes. The stainless steel tracer wire is used in the final stage. Although polyethylene and PVC are the most prevalent for directional drilling projects, neither of these materials allow for a locator to send a signal. A signal is a necessary component when performing a drill and tracer wire is the preferred material to use.

How Does Directional Drilling Work?

Directional drilling is a technique used in the oil and gas industry to drill wells at various angles and directions, rather than just vertically. It allows operators to access reserves that are not directly beneath the drilling location.

Directional drilling techniques have significantly expanded oil and gas exploration and production possibilities. Directional drilling provides access to multiple reservoirs from a single drilling site, enhances production rates, and reduces environmental impact by minimizing the number of drilling locations needed.

Learn more about our stainless steel HDD wire, or contact us today for a quote.