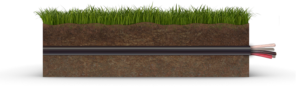

When burying cable lines underground, a major concern is the threat of corrosion from the elements and earth’s electrical charge. Through chemical attack, corrosion can, and in most instances will, over time, degrade the mechanical integrity of a material. To protect metallic structures that are set in various environments, cathodic protection systems can be put in place. A dual insulated cable such as Performance Wire and Cable’s HALAR/HMWPE cables will allow for superior chemical resistance. In conjunction with our HALAR cables, we offer KYNAR/HMWPE cables. KYNAR cables can do everything a HALAR cable can but can also withstand corrosion from chlorine, sulfuric acid, as well as hydrochloric acid, which HALAR is unable to do on its own. Both the HALAR and KYNAR cables are also able to withstand abrasions and crushing.

Cable Corrosion Protection

Buried or water-submerged instances, HALAR and KYNAR cables provide cathodic protection in settings such as:

- Pipelines

- Storage tanks

- Steel pilings

- Well casings

- Water towers

- Marine craft

- Bridges

- Piers

- Railroads

There is excellent resistance against moisture, abrasion, and corrosive chemicals when high molecular weight polyethylene (HMWPE) is used to insulate cables for cathodic protection. The HMWPE converts the anodic (active) sites on the metal surface, by use of electrical current, to cathodic (passive) sites. If the current arrives at the cathode faster than oxygen does, corrosion can be slowed or completely prevented. In the end, our HALAR and KYNAR cables at Performance Wire and Cable make sure your metals last as long as possible.

Performance Wire and Cable is proud to be an official member of NACE, the leading authority on corrosion control solutions. We work directly with other NACE members to ensure our products are the highest quality. As a result, Performance Wire has become a leading global manufacturer and supplier of cathodic protection cable.

Please contact our team today with any questions you have and we will be with you every step of the way throughout the ordering process. Fill out the form to the right for a free quote or call our team today!