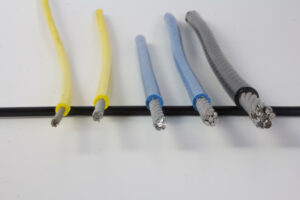

Gone are the days that bare copper wires are acceptable. While copper wires are highly effective, they need insulation in order to keep that effectiveness, no matter the application. Think of wire and cable insulation as a roof to your house – while it doesn’t seem like much, it protects all the valuable items inside

It’s time to learn the difference between various wire insulators. It’s important to know what type of materials are used for each insulator, and which applications they are best suited for.

HMWPE

High molecular weight polyethylene (HMWPE) is thermoplastic wire insulation used most frequently when it comes to cathodic protection. Ideally, HMWPE insulation is suitable for direct burial applications. With its high molecular weight component, this cable insulation is resistant to crushing, abrasion, disfigurement, and more caused by large amounts of weight and pressure. The polyethylene coating provides strength and flexibility, meaning the insulation can take a lot of abuse without damaging the actual cable. It’s common to see HMWPE used for pipelines, storage tanks, underwater cabling, and more.

XLPE

Cross-linked polyethylene insulation is one of the most versatile options on the market. XLPE insulation are resistant to most chemicals involved in the cabling industry, can work at high and low temperatures, protects from water, and allows the cable within to transport and receive high amounts of electric voltage. Hence, insulators like XLPE are popular in the heating and cooling industry, water piping and systems, and any application that calls for a high voltage system. To top it all off? XLPE insulation comes to you at a lower cost than most wire and cable insulators.

HDPE

High-density polyethylene insulation claims to be the toughest, most rugged form of cable insulation. HDPE insulation is not as flexible as others but doesn’t mean it can’t perform when placed in the right application. In fact, many applications such as cable installation, piping, and stainless steel cables call for non-flexible insulation. HDPE insulation is non-corrosive and very resistant to UV rays, meaning it is perfect for straight-line, outdoor applications.

HDPE (high density) is a popular form of HMWPE and is offered by Performance Wire and Cable.

PVC insulation can also be found in the wire and cable industry, especially when it comes to tracer wire and like products. TW, THW, TWU, and UV products can all use PVC insulation.

Wire and cable insulation can be the difference between safe, effective wires and malfunctioning ones that lead to dangerous situations. Selecting the right wire insulation is undoubtedly a huge part of that process; you wouldn’t buy the wrong size roof for your house, right?

Feel free to contact us at Performance Wire and Cable with any questions you may have about wire and cable insulation!